PROFESSIONAL WIRE BAND MANUFACTURER IN CHINA SINCE 1994

Your Trusted Partner in Every Connection

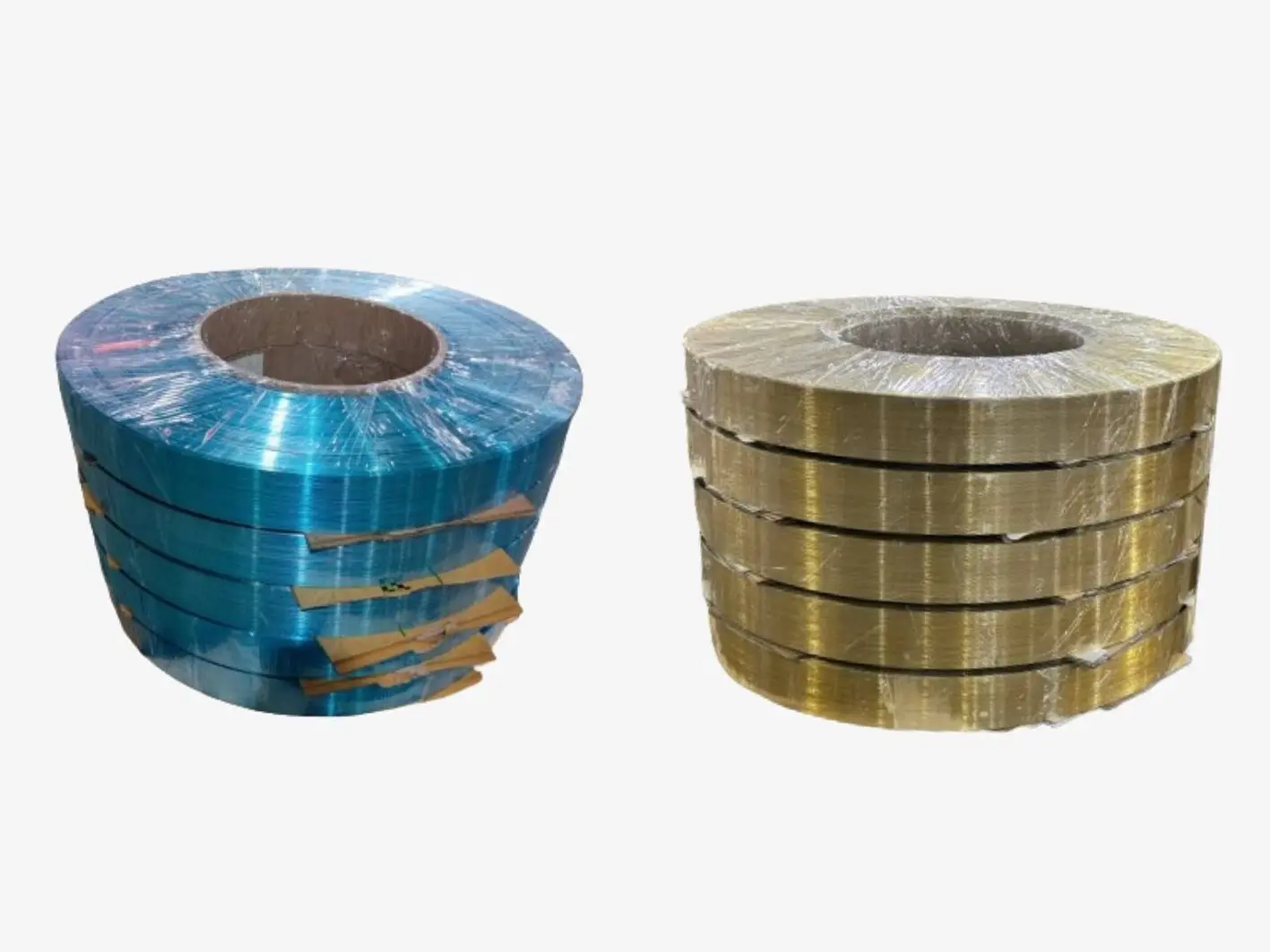

Best Selling Wire Bands

Unicorn specializes in high-quality wire bands engineered for durability and precision. Our range covers 14GA to 22GA, from fine wire to heavy wire, available in a variety of materials, finishes, and colors. Here are some of our most popular wire band models, trusted by staple and nail factories worldwide.

The FAQs About Wire Band

If your question is not listed, please email us right now.

What is the MOQ of the wire band?

The MOQ of the wire band is 2 tons.

Can you make the wire band special color?

Yes. Special color is available. But we would require different MOQ for the special color wire band. It depends on how special the color is.

What is the delivery time for one 20ft' wire band?

One 20ft' wire band delivery time is 25-35 days.

Can you produce INOX wire band?

Yew. We can offer inox 304 and inox 316 wire band.

How many wire bands can you put in one 20ft' container?

The max we can put into one 20ft' container is 50 spools of wire band, which amount to nearly 25 tons.

How many spools of wire band can be stacked together on one pallet?

Usually, a pallet can hold up to 5 spools of wire band, but stacking 3–4 spools is optimal. More than 5 may put excessive pressure on the bottom spool and cause damage.

When is the best time to use wire band?

It's best to use the wire band within six months after you receive it. After that, the glue may not perform at its best

Buying Guide for Wire Band

To help you purchase wire bands smoothly, we have prepared a comprehensive guide covering materials, production process, packaging solutions and using method. For your convenience, this content is structured with direct links, allowing you to quickly jump to the section you are most interested in.

General Material For Wire Band

Copper Coated Wire

Galvanized Wire

Aluminum Wire

Stainless Steel Wire

The Production Process of Wire Band

Our wire band production process is strictly controlled at every stage to ensure consistent product quality.

Step 1: Drawing the wire

Drawing the wire is a process used in the manufacturing of metal products, including nails and staples. It involves pulling a metal rod through a series of dies to reduce its diameter and increase its length. This process aligns the metal’s grain structure, improving its strength and flexibility.

Step 2: Flattening the wire

Flattening the wire is another essential manufacturing process, particularly relevant to the production of staples and some types of nails. This process involves passing the wire through a series of rollers to compress and elongate it, changing its cross-sectional shape from round to flat.

Step 3: Bonding the wire with glue

Bonding the wire with glue is a process used primarily in the production of collated fasteners, such as nails and staples that are grouped together in strips. This technique involves applying a small amount of adhesive to the wires as they are aligned and arranged into these groups. The purpose of the adhesive is to temporarily hold the fasteners together in a fixed arrangement, making them easier to handle and load into tools like nail or staple guns.

Step 4: Packing

Packaging is the final step in the wire band manufacturing process. At this stage, the wire band is wound into uniform coils, typically around 500 kg each, and securely fastened to maintain proper tension. Depending on customer requirements, the coils can be wound on either plywood spools or cardboard cores. The coils are then wrapped with PE film to protect them from moisture, rust, and edge damage during storage and long-distance transportation. This process ensures that the wire bands remain stable, safe, and convenient for handling and subsequent staple production.

Want to know how to compress lead times?

Have regular orders and want to compress lead time, talk to our sales engineer to find the best solution

The Packaging of the Wire Band

We offer two packaging options for wire bands to ensure safe transportation and cost efficiency.

Wire Band with Plywood Spool

- Highly protective, capable of withstanding external impacts

- Easy to load and unload

For staple and nail factories, using this packaging is the most worry-free and convenient option because plywood provides high protection and ease of operation. However, the cost of plywood is high, and its disposal or recycling needs to be considered after use

Wire Band with Cardboard

- Cost-effective and economically efficient

For staple factories with high wire band demand, cardboard packaging is a cost-effective choice. While less protective than plywood, cardboard’s lower cost offsets potential losses in large-scale use. Plus, it eliminates concerns about plywood disposal, making it a more practical and economical option

WHY CHOOSE UNICORN

China Top 5 Trusted Staples & Nails Manufacturer

Moderate Price

Competitive prices combined with unparalleled quality ensure that every penny you spend is worthwhile.

Expert Sales Engineer

Our sales engineers combine deep industry knowledge, extensive experience, and fluency in English to facilitate effective communication.

Fast Delivery

Equipped with numerous advanced machines and more than 250 skilled workers, Unicorn ensures rapid and efficient manufacturing.

Quality Assurance

We guarantee reliability through stringent testing, ensuring our products consistently meet high standards of performance and durability.

Feel free to contact Our Sale Engineer

Whether you have product questions, need a customized quote, or want to explore business solutions, our sales engineers are just a message away. Contact us today for a prompt response and expert guidance – we look forward to supporting your success.

+86-15620082770

zeta@unicon-fasteners.com