PROFESSIONAL STAPLE MANUFACTURER IN CHINA SINCE 1994

Your Trusted Partner in Every Connection

Best Selling Staples

Unicorn specializes in high-quality industrial staples built for durability and precision. Our range covers 14GA to 22GA, from fine wire to heavy wire, with different materials, finishes, and colors. Here are some of our most popular staples, widely used in construction, furniture, packaging, and more.

71 SERIES STAPLE

- Item: 71 series

- Gauge: 22GA

- Crown: 9.00mm

- Wire: 0.75 x 0.54mm

- Length: 4 to 16mm

- Strips of 167/179/182

- Diffenert color is available for choosing

A11 SERIES STAPLE

- Item: A11 Series

- Gauge: 20GA

- Crown: 10.55mm

- Wire: 1.26 x 0.49mm

- Length: 6 to 16mm

- Strips of 84

- Diffenert color is available for choosing

10J SERIES STAPLE

- Item: 10J series

- Gauge: 20GA

- Crown: 11.2 mm

- Wire: 1.26 x 0.50 mm

- Length: 4 to 25 mm

- Strips of 100

- Diffenert color is available for choosing

80 SERIES STAPLE

- Item: 80 Series

- Gauge: 21GA

- Crown: 12.80mm

- Wire: 0.90 x 0.70mm

- Length: 4 to 14mm

- Strips of 125/143/150

- Diffenert color is available for choosing

90 SERIES STAPLE

- Item: 90 Series

- Gauge: 18GA

- Crown: 5.7mm

- Wire: 1.25 x 1.00mm

- Length: 10 to 45mm

- Strips of 100

- Diffenert color is available for choosing

N SERIES STAPLE

- Item: N Series

- Gauge: 16GA

- Crown: 10.55mm

- Wire: 1.58 x 1.35mm

- Length: 16 to 64mm

- Strips of 70

- Diffenert color is available for choosing

35 SERIES STAPLE

- Item: 35 Series

- Gauge: 16GA

- Crown: 34.7mm

- Wire: 2.23 x 0.82mm

- Length: 15 to 22mm

- Strips of 50

- Cooper and silver is available for choosing

BSC15 SERIES STAPLE

- Item: BCS15 Series

- Gauge: 15.5GA

- Crown: 12.5mm

- Wire: 1.83 x 1.62mm

- Length: 25 to 44mm

- Strips of 45

- Diffenert color is available for choosing

The FAQs About Staples

If your question is not listed, please email us right now.

Can you manufacture custom staples for unique applications?

Yes, we specialize in manufacturing custom staples designed to meet specific needs. Please tell us the specifiaction you need and we will make the drawing for you individually. Or please provide your drawing and we will produce it based on your drawing. Once everything is confirmed, then we start production for you to ensure the precision.

What kind of steel do you use to produce your staples?

Our staples are primarily made from low carbon steel Q235 (C1018).

For woods requiring higher tensile strength, we provide alternatives like QYL2 and medium carbon steel to ensure durability.

What are the suitable staple sizes for upholstery work?

For upholstery tasks, fine and medium wire staples are recommended as they provide the necessary hold while minimizing damage to delicate fabrics.

How to choose the correct staple leg length

An excellent rule for choosing the right staple length for your application is to take the thickness of the material you are fastening and multiply it by three. For example, if the material you are fastening is 6mm thick, the ideal staple leg length would be 18mm. If this specific length is not available, opt for the closest longer leg length available.

When working with thin materials, such as fabric or other thin substances, it is advisable to add 4mm to the thickness of the material used. For instance, if your material is 3mm thick, use a 7mm leg length staple. If you can't find an exact match, select the closest shorter leg length available to avoid penetration issues.

For hard materials, such as hardwood or metals, the required staple leg length should be twice as long as the thickness of the material to ensure a robust and secure fastening. If you're fastening 2mm thick hardwood, a staple with a leg length of 4mm is recommended. As with other materials, if the exact length is not available, choose the closest shorter leg length available.

How to define staples are of high quality?

High-quality staples are defined by their perfectly accurate sizing, which ensures they slide smoothly through the staple gun’s magazine. They should have the right amount of adhesive to keep the staple bar intact yet allow individual staples to separate easily when used. Additionally, the wire must be firm enough to cleanly perforate the material being stapled.

Can you provide private packaging design?

Sure, we can definitely help design the outer packaging just the way you need it.

How do I select the best staple for my project

1)Staple Fit and Compatibility

Stapler Compatibility and fitness: Ensure staples fit your industrial stapler or staple gun.

2)Type of Wire

Fine Wire Staples: For delicate materials like fabrics; minimal visibility.

Medium Wire Staples: Stronger hold for medium-density materials like wood.

Heavy Wire Staples: Ideal for construction and thick materials.

3)Crown Width

Narrow Crown Staples: Less noticeable, deeper penetration for precise work.

Medium Crown Staples: Broader coverage, suitable for furniture.

Wide Crown Staples: Used for packaging, focusing on utility.

4)Leg Length

Rule of Thumb: Multiply material thickness by three to determine leg length.

5)Type of Metal

Galvanized Steel: Rust-resistant, ideal for outdoor use.

Copper-Coated: Suitable for indoor, dry conditions.

Aluminum: Non-magnetic, easy to cut, for minimal electronic interference.

Stainless Steel: Highest corrosion resistance, for outdoor and marine use.

6)Environmental Considerations

Consider moisture, chemical exposure, and conditions that affect material choice.

7)Project Requirements

Consider aesthetics, structural integrity, and staple volume for project durability.

Buying Guide for Staple

To help you purchase staples smoothly, we have prepared a comprehensive guide covering staple basics, materials, applications, key quality factors, production process, and packaging solutions. For your convenience, this content is structured with direct links, allowing you to quickly jump to the section you are most interested in.

Basic Knowledge of the Staple

Definition of Staples

A staple is a type of two-pronged fastener, usually metal, used for joining, gathering, or binding materials together. We can devide the staple into 2 categories: stationery staples and industrial staples. For industrial staples, there are few standards for staple size, length and thickness. This has led to many different incompatible staples and staplers systems, all serving the same purpose or applications.

Staple wire thickness is measured by its “gauge.” This is a measurement of a wire’s diameter. The system of identifying wire by its diameter was originally developed 1857 to specify electrical wires by their current carrying capacity. Oddly, the higher the number, the thinner the wire. Wire is referred to as fine, medium and heavy.

Staple Wire

Fine Wire Staples

Medium Wire Staples

Heavy Wire Staples

Staple Crown

Narrow Crown Staples

Medium Crown Staples

Wide Crown Staples

Staple Points

Chisel Point

Divergent Point

General Material For Staple

Copper Coated Wire

Galvanized Wire

Aluminum Wire

Stainless Steel Wire

Application of the Staples

Important Points of the Staple

Shearing Force

Shearing force of a staple refers to the force required to shoot a staple from a row, influenced by the amount and quality of adhesive on the staples. More adhesive or stronger adhesive increases the shearing force. For manual staplers, higher shearing force means more exertion is needed. For pneumatic or electric staplers, the shearing force is less critical due to the power of these tools.

Coating Thickness

Coating thickness of a staple refers to the depth of the material layer applied on the surface of the staple, which can include metals like zinc or copper, or other protective or functional coatings. This thickness is crucial because it impacts both the performance and longevity of the staple, especially in terms of corrosion resistance and overall durability. Unicorn standard coating thickness is 1-2μm(10-15g)

Tensile Strength

Tensile strength of a staple refers to the maximum amount of tensile stress that the staple can withstand before breaking. This is a critical parameter in the design and quality assurance of fasteners because it directly affects the staple’s ability to hold materials together under tension. Unicorn has different kinds of materials for customer choosing including various low carbon steel, medium carbon steel and high carbon steel. The tensile strength is from 900-1500Mpa which can suitable for different hardness of the wood.

Staple Point Angle

Some customers have requirement about the staple point engle. Usually we called it “β”. When the angle is samll, the point is sharp and easily penetrate into the wood. Unicorn’s standard angle is 60°±5°

The Production Process of the Staples

Our staple production process is strictly controlled at every stage to ensure consistent product quality.

Step 1: Drawing the wire

Drawing the wire is a process used in the manufacturing of metal products, including nails and staples. It involves pulling a metal rod through a series of dies to reduce its diameter and increase its length. This process aligns the metal’s grain structure, improving its strength and flexibility.

Step 2: Flattening the wire

Flattening the wire is another essential manufacturing process, particularly relevant to the production of staples and some types of nails. This process involves passing the wire through a series of rollers to compress and elongate it, changing its cross-sectional shape from round to flat.

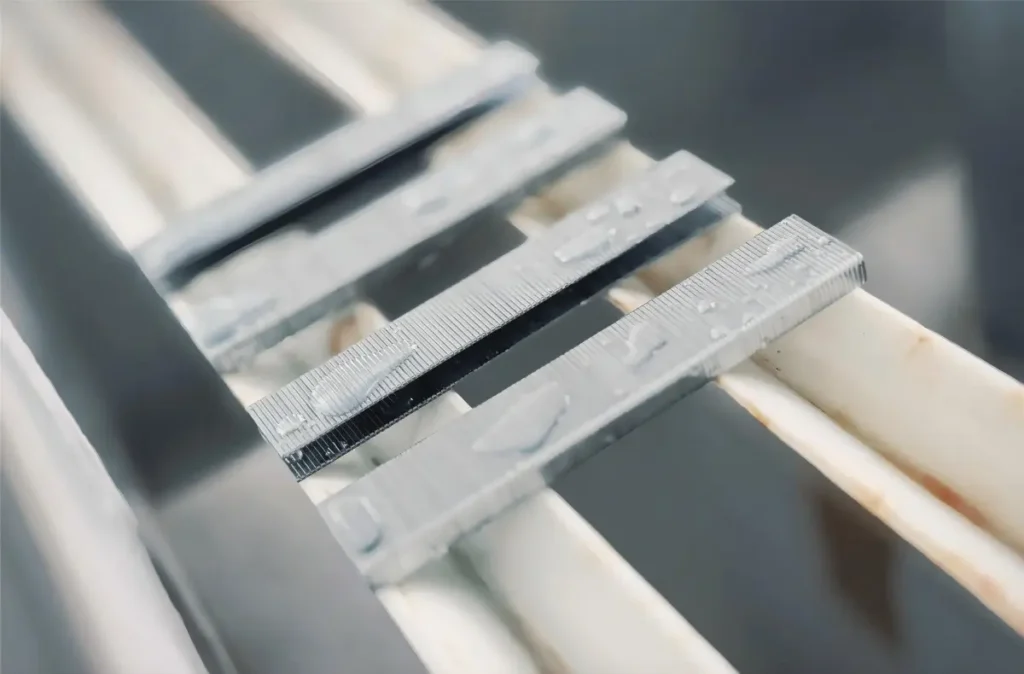

Step 3: Bonding the wire with glue

Bonding the wire with glue is a process used primarily in the production of collated fasteners, such as nails and staples that are grouped together in strips. This technique involves applying a small amount of adhesive to the wires as they are aligned and arranged into these groups. The purpose of the adhesive is to temporarily hold the fasteners together in a fixed arrangement, making them easier to handle and load into tools like nail or staple guns.

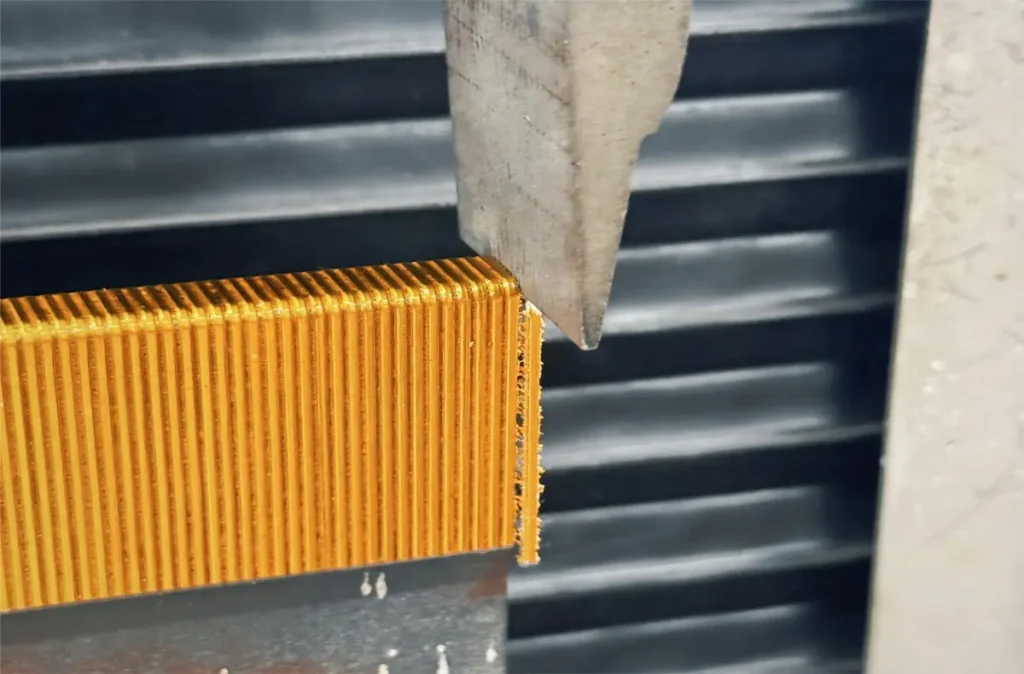

Step 4: Pressing

Punching of the staple and nail refers to a manufacturing process used to create the final form staples and nails. This process involves using a punch and die set to cut and shape the wire into individual fasteners with precise dimensions and features.

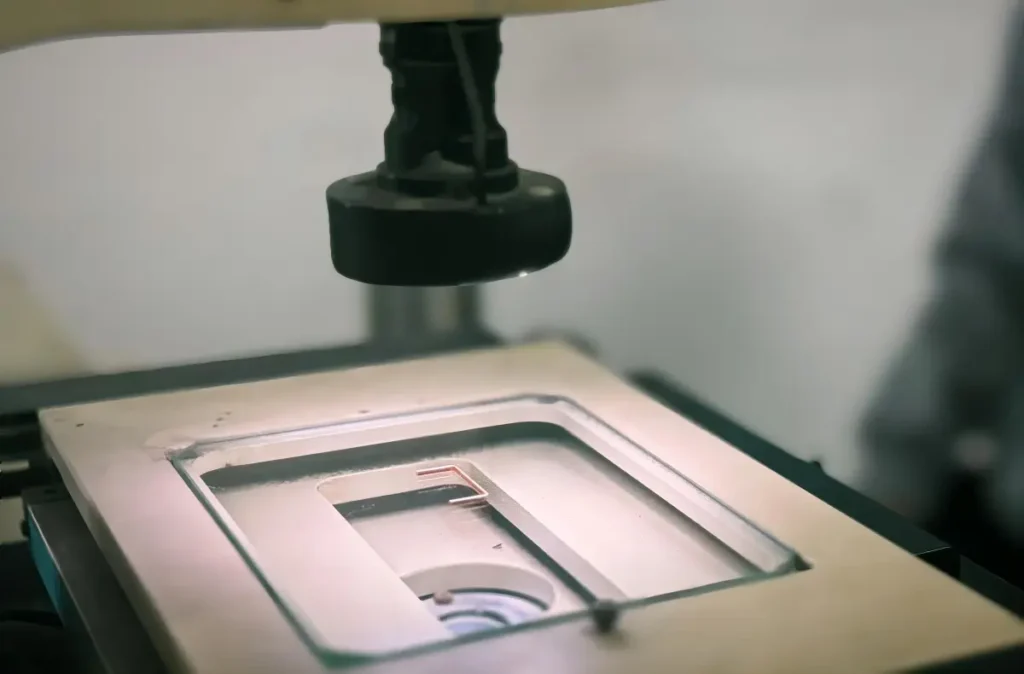

Step 5: Packing

The packaging process for staples and nails is a crucial final step in manufacturing that involves placing the finished products into appropriate containers or packages to protect them, facilitate their handling, and enhance their presentation. This process is vital for ensuring the products reach the end-users in good condition and are easy to distribute and use.

Want to know how to compress lead times?

Have regular and stable orders and want to compress lead time, talk to our sales engineer to find the best solution

The Packaging of the Staples

From standard to customized, our packaging solutions help you balance efficiency and brand identity

Neutral Packaging

- Packaging cost is low

- MOQ is low

- Lead time is shorter than OEM design

Usually wholesalers and retailers needs this kind of packaging becasue they don’t have the need to expose the brand.Neutral packaging is more flexible when placing order because Unicorn have many stocks of neutral packaging and customers no need to care about the MOQ.

Private Label/OEM Designed

- High Brand Exposure

- Higher margin

Usually distributors and brand owner have the needs of exposure the brands. Unicorn has a design team and can help with designing for you. If you hope to design multicolor of the brand design, please feel free to contact us.

WHY CHOOSE UNICORN

China Top 5 Trusted Staples & Nails Manufacturer

Moderate Price

Competitive prices combined with unparalleled quality ensure that every penny you spend is worthwhile.

Expert Sales Engineer

Our sales engineers combine deep industry knowledge, extensive experience, and fluency in English to facilitate effective communication.

Fast Delivery

Equipped with numerous advanced machines and more than 250 skilled workers, Unicorn ensures rapid and efficient manufacturing.

Quality Assurance

We guarantee reliability through stringent testing, ensuring our products consistently meet high standards of performance and durability.

Feel free to contact Our Sale Engineer

Whether you have product questions, need a customized quote, or want to explore business solutions, our sales engineers are just a message away. Contact us today for a prompt response and expert guidance – we look forward to supporting your success.

+86-15620082770

vincent@unicon-fasteners.com