PROFESSIONAL BRAD NAIL & PIN MANUFACTURER IN CHINA SINCE 1994

Your Trusted Partner in Every Connection

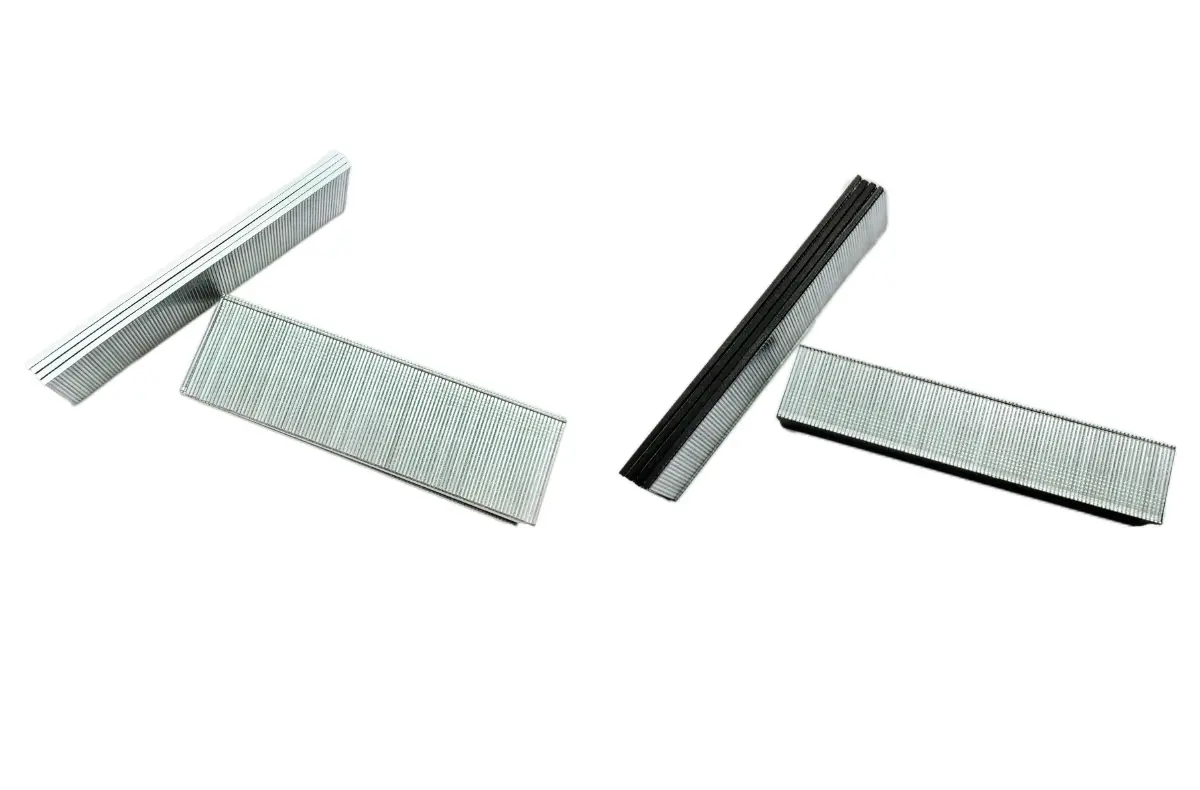

Best Selling Nails

Unicorn specializes in high-quality industrial nails and pins engineered for durability and precision. Our product range covers 14GA to 23GA, including both straight and angled nails, available in a variety of materials, finishes, and colors. These nails are widely used in construction, cabinetry, furniture manufacturing, interior decoration, and more.

P6 SERIES PIN

- Item: P6 series

- Gauge:23GA

- Wire: 0.67 x0.67mm

- Length: 4 to 50mm

- Strips of 100

- Diffenert material is available for choosing

F SERIES BRAD NAIL

- Item: F series

- Gauge: 18GA

- Wire:1.25x1.00mm

- Head Width: 2.00mm

- Length: 10 to 50mm

- Strips of 100

- Diffenert material is available for choosing

T SERIES BRAD NAIL

- Item: T series

- Gauge: 16GA

- Wire:1.58x1.35mm

- Head Width: 2.90mm

- Length: 15 to 64mm

- Strips of 50

- Diffenert material is available for choosing

AF SERIES 20 DEGREE NAIL

- Item: AF series

- Gauge: 16GA

- Wire:1.58x1.35mm

- Head Width: 2.80mm

- Length: 32 to 64mm

- Strips of 50

- Diffenert material is available for choosing

FN SERIES 25 DEGREE NAIL

- Item: FN series

- Gauge: 25GA

- Wire:1.87x1.62mm

- Head Width: 3.20mm

- Length: 32 to 64mm

- Strips of 43

- Diffenert material is available for choosing

DA SERIES 34 DEGREE NAIL

- Item: DA series

- Gauge: 15GA

- Wire:1.76x1.76mm

- Head Width: 3.10mm

- Length: 25 to 64mm

- Strips of 50/100

- Diffenert material is available for choosing

The FAQs About Brad Nail and Pin

If your question is not listed, please email us right now.

What are the differences between straight nails, angled nails, and pins?

Straight Nails: These have a flat, straight shank and are used in various general construction and carpentry applications. They are ideal for tasks requiring strong holding power.

Angled Nails: These nails have a shank that is slightly bent or angled. They are often used in tight or awkward spaces where a straight nailer cannot fit. The angled design allows for easier access and better alignment in such situations.

Pins: Pins are very thin, small nails used primarily for delicate woodworking projects, like trim or molding. They are less visible than regular nails and are perfect for tasks where a discreet fastening is required.

what is the application of 15GA DA nails?

15GA DA nails are an essential tool for professionals working on furniture, cabinetry, molding, trim, baseboards, and door and window casings. Their strong holding power and ability to drive through hardwoods make them versatile and reliable for various applications.

What materials are these nails typically made from?

Most straight and angled nails are made from galvanized steel like Q235(C1018).Some are made from stainless stell so that they can be used outdoors.

Can these nails be used in all types of wood and materials?

While straight and angled nails can be used in most types of wood, the specific type of wood and the nail's gauge should be considered to prevent splitting or ineffective fastening. Pins are generally used in softer woods and for fine woodworking tasks.

Can you make the 23GA headless pin silver color?

Yes. We can produce every color you need. The cooper is most common. But some customers will need 23GA pin in silver and pale green.

What kind of finish of 15GA DA nail do you provide?

Bright, Galvanize, Stainless Steel including 304 and 316

What elso straight nail model can you provide?

We can provide P8, DT/ND nail and so on.

Can you provide private packaging design?

Sure, we can definitely help design the outer packaging just the way you need it.

Buying Guide for Brad Nail and Pin

To help you purchase brad nails and pins smoothly, we have prepared a comprehensive guide covering basics, important points, materials, applications, production process, and packaging solutions. For your convenience, this content is structured with direct links, allowing you to quickly jump to the section you are most interested in.

Basic Knowlege of Brad Nail and Pin

Definition

Brad nails, also known as collated nails, are a series of wires sticked by glue. The nails can be straight and angled. They have different wire dias like 14GA wire, 15GA wire, 16GA wire and 18GA wire.

Pins, unlike brad nails, they don't have nail head. They have diffent wire dias like 18GA wire, 21GA wire and 23GA wire.

DA nails are a series nails sticked by tape. And the shape of DA nail head is similar to letter"D". DA nails are set at 34 degree. Unlike brad nails and pins, DA nail only have one wire dia-15GA

Important Points of the Nails

Shearing Force

Shearing force of a nail refers to the force required to shoot a nail from a row, influenced by the amount and quality of adhesive on the nails. More adhesive or stronger adhesive increases the shearing force. For manual staplers, higher shearing force means more exertion is needed. For pneumatic or electric staplers, the shearing force is less critical due to the power of these tools.

Coating Thickness

Coating thickness of a nail refers to the depth of the material layer applied on the surface of the nail, which can include metals like zinc or copper, or other protective or functional coatings. This thickness is crucial because it impacts both the performance and longevity of the nail, especially in terms of corrosion resistance and overall durability. Unicorn standard coating thickness is 1-2μm(10-15g)

Tensile Strength

Tensile strength of a nail refers to the maximum amount of tensile stress that the nail can withstand before breaking. This is a critical parameter in the design and quality assurance of fasteners because it directly affects the nail’s ability to hold materials together under tension. Unicorn has different kinds of materials for customer choosing including various low carbon steel, medium carbon steel and high carbon steel. The tensile strength is from 900-1500Mpa which can suitable for different hardness of the wood.

Nail Point Degree

Some customers have requirement about the staple point engle. Usually we called it “β”. When the angle is samll, the point is sharp and easily penetrate into the wood. Unicorn’s standard angle is 60°±5°

Brad Nails VS Finish Nails

Brad nails, made from 18-gauge wire and 1/2 to 2 inches long, are ideal for delicate woodworking projects like trim, paneling, and molding due to their thin diameter and small head, which minimize visible holes. However, they lack holding strength and can bend easily. Finish nails, made from 15- or 16-gauge wire and 1 to 3 1/2 inches long, are suited for substantial projects like cabinetry, baseboards, and crown molding, offering greater holding power but leaving more noticeable holes that require filling and finishing.

Angled Nails VS Straight Nails

Angled nails, available in 20°, 25°, and 34° variants, excel in tight corners and confined spaces, ideal for installing trim in hard-to-access areas. Though limited to sizes between 32mm and 64mm and more expensive, they offer superior maneuverability. Conversely, straight nails, set at a 90° angle, are perfect for straightforward applications like attaching decorative trim and fixtures. They support a wider size range (10mm to 64mm) and are more affordable. Choosing between them hinges on prioritizing maneuverability or cost and size versatility.

15GA FN Nails VS 15GA DA Nails

Choosing between FN and DA 15-gauge nails for your angled finish nailer depends on your project and nail gun design. FN nails, with a 25-degree collation and rectangular head, are reliable for various finishing tasks and are glued together, making them sturdy. DA nails, with a 33- or 34-degree collation and a “D-head” shape, are taped and ideal for precision work in tight spaces. FN nails are suited for Bostitch guns, while DA nails are designed by Senco, each offering unique benefits to enhance your finishing projects.

Paint on the Nail Head

Some customers in finish carpentry indusrty have color requirement about the nail head because they need the nail to match the material color they are using. They hope the nails to be pretty much invisible, which is great for projects. Besides, the paint on the nail head can also protect the nails from rust by blocking out moisture. At Unicorn, we customize the color of our nail heads to fit your projects-whether you need them in white, brow, black, or any other color. Contact us for your customized nail head color!

General Material For Nails

Galvanized Wire

Aluminum Wire

Stainless Steel Wire

Application of the Nails

The Process Flow of the Brad Nail

Our brad nail production process is strictly controlled at every stage to ensure consistent product quality.

Step 1: Drawing the wire

Drawing the wire is a process used in the manufacturing of metal products, including nails and staples. It involves pulling a metal rod through a series of dies to reduce its diameter and increase its length. This process aligns the metal’s grain structure, improving its strength and flexibility.

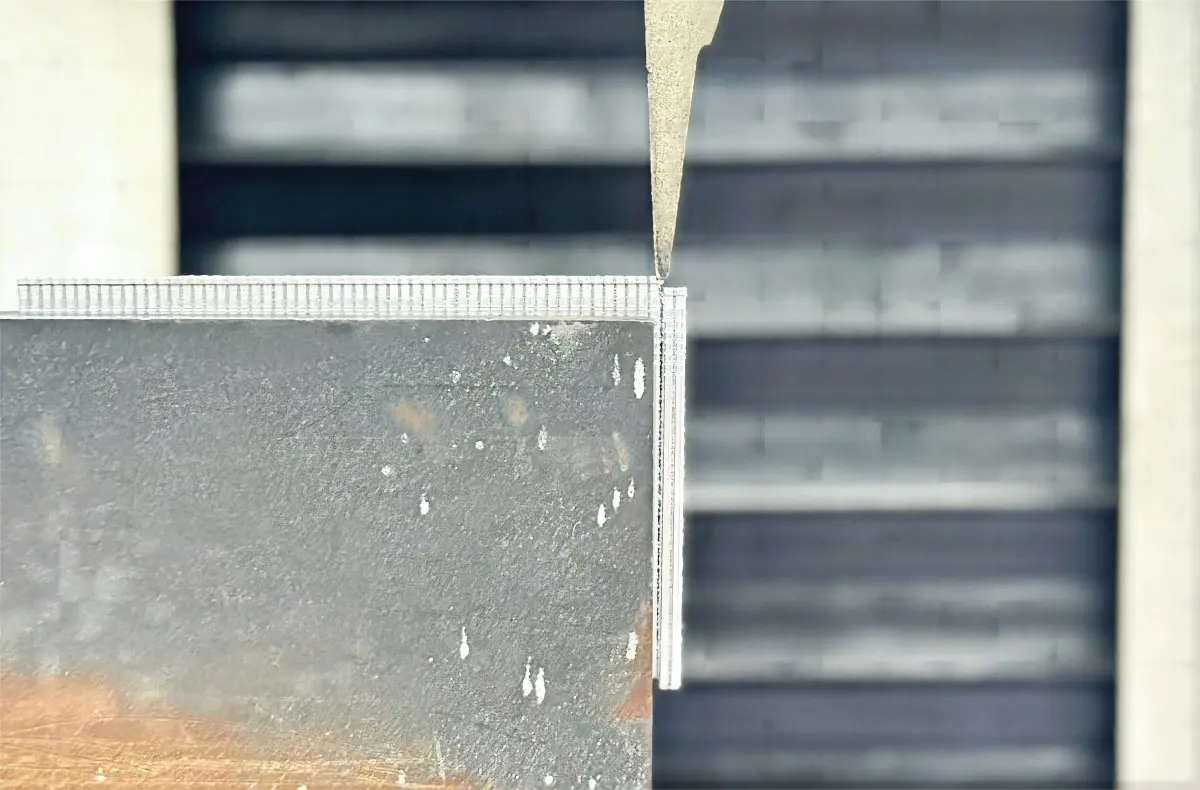

Step 2: Flattening the wire

Flattening the wire is another essential manufacturing process, particularly relevant to the production of staples and some types of nails. This process involves passing the wire through a series of rollers to compress and elongate it, changing its cross-sectional shape from round to flat.

Step 3: Bonding the wire with glue

Bonding the wire with glue is a process used primarily in the production of collated fasteners, such as nails and staples that are grouped together in strips. This technique involves applying a small amount of adhesive to the wires as they are aligned and arranged into these groups. The purpose of the adhesive is to temporarily hold the fasteners together in a fixed arrangement, making them easier to handle and load into tools like nail or staple guns.

Step 4: Punching and Packing

Punching of the staple and nail refers to a manufacturing process used to create the final form staples and nails. This process involves using a punch and die set to cut and shape the wire into individual fasteners with precise dimensions and features. The packaging process for staples and nails is a crucial final step in manufacturing that involves placing the finished products into appropriate containers or packages to protect them, facilitate their handling, and enhance their presentation. This process is vital for ensuring the products reach the end-users in good condition and are easy to distribute and use.

Want to know how to compress lead times?

Have regular and stable orders and want to compress lead time, talk to our sales engineer to find the best solution

The Process Flow of DA Nails

Our DA nail production process is strictly controlled at every stage to ensure consistent product quality.

Step 1: Drawing the Wires and Making the Nails

Drawing the wire is a process used in the manufacturing of metal products, including nails and staples. It involves pulling a metal rod through a series of dies to reduce its diameter and increase its length. This process aligns the metal’s grain structure, improving its strength and flexibility.

Step 2: DA nail collation

Flattening the wire is another essential manufacturing process, particularly relevant to the production of staples and some types of nails. This process involves passing the wire through a series of rollers to compress and elongate it, changing its cross-sectional shape from round to flat.

Want to know how to compress lead times?

Have regular and stable orders and want to compress lead time, talk to our sales engineer to find the best solution

The Packaging of the Brad Nails and Pins

From standard to customized, our packaging solutions help you balance efficiency and brand identity

Neutral Packaging

- Packaging cost is low

- MOQ is low

- Lead time is shorter than OEM design

Usually wholesalers and retailers needs this kind of packaging becasue they don’t have the need to expose the brand.Neutral packaging is more flexible when placing order because Unicorn have many stocks of neutral packaging and customers no need to care about the MOQ.

Private Label/OEM designed

- High Brand Exposure

- Higher margin

Usually distributors and brand owner have the needs of exposure the brands. Unicorn has a design team and can help with designing for you. If you hope to design multicolor of the brand design, please feel free to contact us.

WHY CHOOSE UNICORN

China Top 5 Trusted Staples & Nails Manufacturer

Moderate Price

Competitive prices combined with unparalleled quality ensure that every penny you spend is worthwhile.

Expert Sales Engineer

Our sales engineers combine deep industry knowledge, extensive experience, and fluency in English to facilitate effective communication.

Fast Delivery

Equipped with numerous advanced machines and more than 250 skilled workers, Unicorn ensures rapid and efficient manufacturing.

Quality Assurance

We guarantee reliability through stringent testing, ensuring our products consistently meet high standards of performance and durability.

Feel free to contact Our Sale Engineer

Whether you have product questions, need a customized quote, or want to explore business solutions, our sales engineers are just a message away. Contact us today for a prompt response and expert guidance – we look forward to supporting your success.

+86-15620082770

vincent@unicon-fasteners.com