PROFESSIONAL COIL NAIL MANUFACTURER IN CHINA SINCE 1994

Your Trusted Partner in Every Connection

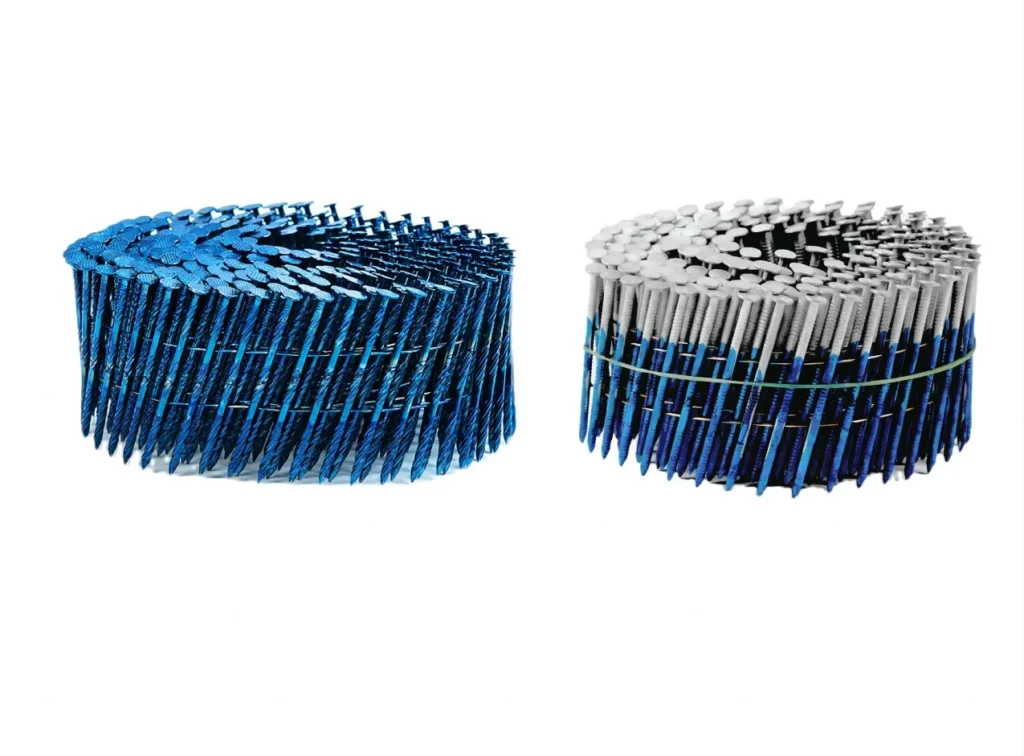

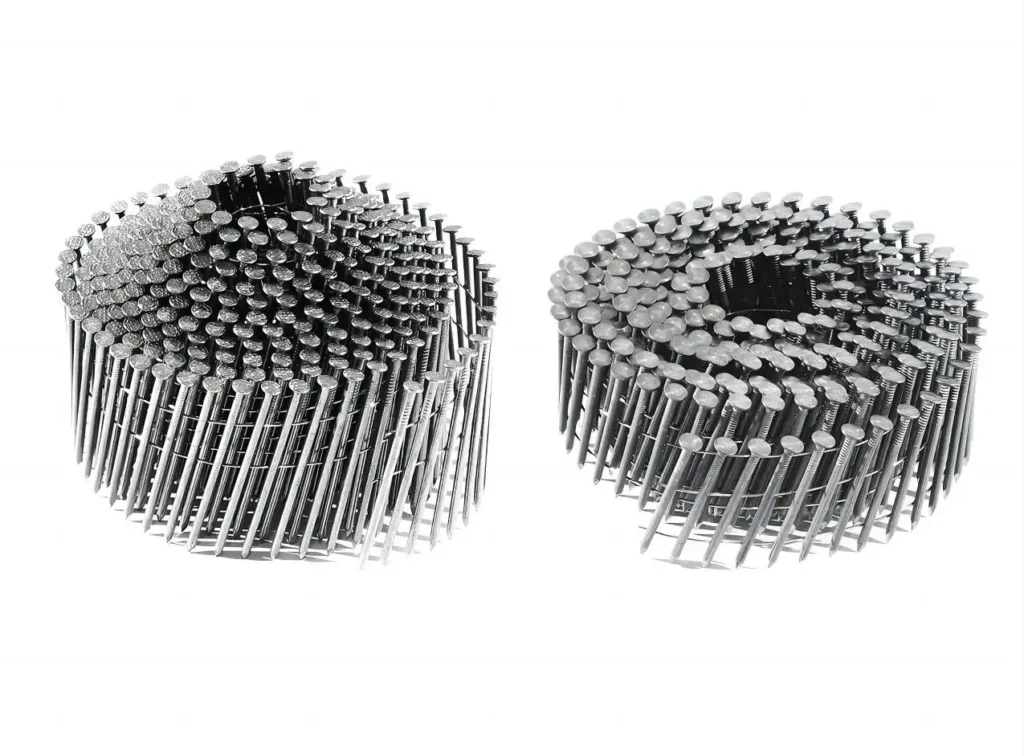

Best Selling Coil Nails

Unicorn specializes in high-quality coil nails engineered for durability and precision. Our range covers wire diameters from 2.1mm to 3.8mm and lengths from 32mm to 130mm, available in various materials, finishes, and colors. From small coil nails to jumbo coil nails, we offer reliable solutions for diverse applications. Here are some of our most popular coil nails, widely used in pallets, flooring, fencing, and more.

BRIGHT COIL NAIL

- Item: 15 Degree Wire Welded Bright Coil Nail

- Wire Dia: 2.1-3.8mm

- Length: 32mm-130mm

- Diffenert color is availablefor choosing

GALVANIZED COIL NAIL

- Item: 15 Degree Wire Welded Galvanized Coil Nail

- Wire Dia: 2.1-3.8mm

- Length: 32mm-130mm

- Diffenert color is availablefor choosing

The FAQs About Coil Nail

If your question is not listed, please email us right now.

What material are coil nails typically made of?

Q235&Q195 Steel.

What shank styles are available?

Smooth(SM), Ring(R) & Screw(SC).

What is the production lead time for the coil nails?

It is upon the quantity of the order. Normally the lead time of coil nails is 30-40 days after confirming the order.

Are custom or OEM services available?

Yes. We can design the packages of our customers’ requirements

What are the applications of coil nails?

1. Sheathing.

2. Ply bracing.

3. Fencing fixation.

4. Timber & softer pine framing material.

5. Composition roofing.

6. Underlayments.

7. Fiber cement boards.

8. Cabinet and furniture frames.

How many nails are generally found in a coil?

250 nails per coil, 300 nails per coil, 350 nails per coil, 30 coils/carton, 35 coils/carton

or as customers' requirement

How many cartons per pallets?

Usually we load 40 cartons per pallets. But we can put as per customers's requirements.

Can you provide samples for checking quality?

Yes. Samples are availbale for checking quality and can be prepared within 3 days.

Buying Guide for Coil Nails

To help you purchase coil nails smoothly, we have prepared a comprehensive guide covering basics, finishs, important points, applications,production process, and packaging solutions. For your convenience, this content is structured with direct links, allowing you to quickly jump to the section you are most interested in.

Basic Knowledge of Coil Nail

Definition of Coil Nails

Coil nails, also known as wire-welded collated nails, are a series of nails connected by brass-coated welding wire and arranged in a circle. The nails are set at a 15-16 degree angle and are designed to be loaded into specific nail guns for use.

The diameter of coil nails ranges from a minimum of 2.1mm (0.083") to a maximum of 3.8mm (0.149"), with lengths varying from 32mm(1-1/4") to 130mm(5-1/8"). The shank of coil nails comes in different styles to accommodate various applications.

Available Finishes of Coil Nail

Bright

Electro-Galv.

Hot-Dipped Galv

Stainless Steel

Important Points You Need to Know About Coil Nail

Jumbo Coil VS Small Coil

Jumbo coil nails, also known as high load jumbo coil nails, contain 1,000 to 3,000 nails per coil, making them ideal for large-scale industrial applications like pallet manufacturing, crate building, and robotic manufacturing, ensuring reliable performance. In contrast, small coil nails hold 150-400 nails and are used in small portable nailers. Jumbo coil nails save a lot of time by reducing reloads, while small coil nails offer greater flexibility for various tasks.

Full Coating VS Half Coating

For bright coil nails, we offer two surface treatments: full coating and half coating. The coatings come in various colors such as yellow, blue, and red. Full coating means the entire nail is coated in one color to prevent rust. Half coating involves applying a transparent coating first, followed by a colored coating, making the nails look beatuiful but at a higher cost. For galvanized nails, half coating is also available to choose from.

Conical Coil VS Flat Coil

Conical coils and flat coils differ primarily in shape. Conical coil nails are layered from the outside of the coil to its center, forming a cone. In contrast, flat coils are flat on the top surface.When using conical coils, ensure that your nail gun is specifically designed for conical nails to avoid jamming or misfires. Similarly, flat coils require nail guns that are compatible with flat nails. Using the incorrect type of coil can lead to tool malfunctions and potential safety hazards. Always match the coil type to the appropriate nail gun for optimal performance and safety.

Smooth VS Ring VS Screw

Smooth, Ring, and Screw shank are the most common for coil nails. Smooth shank nails are easy and fast to drive, versatile, and affordable but offer less holding power, ideal for general woodworking, framing, and finishing. Ring shank nails have annular threads for greater withdrawal resistance, perfect for siding, roof decking, and subfloors. Screw shank nails combine nail ease with screw holding power, offering superior pull-through resistance, suitable for decking, flooring, and hardwood applications.

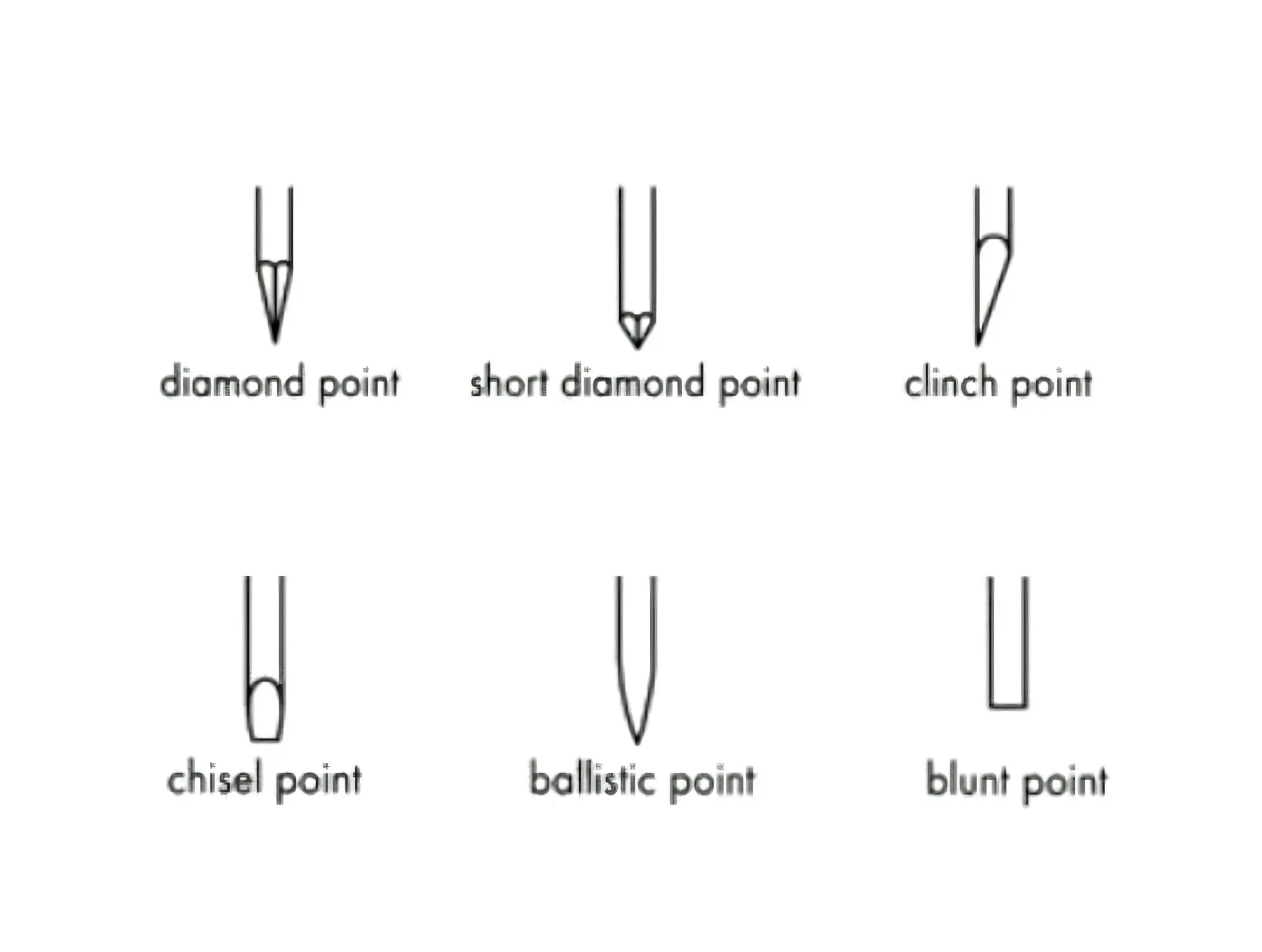

Various Nail Points for Choosing

Flat VS Logo VS Checkered

When selecting nail heads, it’s essential to understand their specific features. Flat heads provide a large striking surface and additional holding power, making them ideal for applications where the nail head remains visible. Special logo heads offer unique patterns for enhanced grip and aesthetics. Checkered heads feature a grid-like pattern to prevent slippage during hammering from awkward angles, ensuring a secure and efficient installation. Each type serves a distinct purpose, optimizing performance for various construction needs.

Application of the Coil Nails

The Packaging of the Coil Nail

From standard to customized, our packaging solutions help you balance efficiency and brand identity

Neutral Packaging

- Packaging cost is low

- MOQ is low

- Lead time is shorter than OEM design

Usually wholesalers and retailers needs this kind of packaging becasue they don’t have the need to expose the brand.Neutral packaging is more flexible when placing order because Unicorn have many stocks of neutral packaging and customers no need to care about the MOQ.

Private Label/OEM designed

- High Brand Exposure

- Higher margin

Usually distributors and brand owner have the needs of exposure the brands. Unicorn has a design team and can help with designing for you. If you hope to design multicolor of the brand design, please feel free to contact us.

Production Process of Coil Nails

Our coil nail production process is strictly controlled at every stage to ensure consistent product quality.

Step 1: Drawing the Wires and Making the Nails

Etiam sit amet orci eget eros faucibus tincidunt. Praesent blandit laoreet nibh. Praesent venenatis metus at tortor pulvinar varius. Vestibulum suscipit nulla quis orci. Nam ipsum risus, rutrum vitae, vestibulum eu, molestie vel, lacus.

Step 2: Threading the shank for the nail

Etiam sit amet orci eget eros faucibus tincidunt. Praesent blandit laoreet nibh. Praesent venenatis metus at tortor pulvinar varius. Vestibulum suscipit nulla quis orci. Nam ipsum risus, rutrum vitae, vestibulum eu, molestie vel, lacus.

Step 3: Paint coating then Making the Nails in Coils then Packing

Etiam sit amet orci eget eros faucibus tincidunt. Praesent blandit laoreet nibh. Praesent venenatis metus at tortor pulvinar varius. Vestibulum suscipit nulla quis orci. Nam ipsum risus, rutrum vitae, vestibulum eu, molestie vel, lacus.

Want to know how to compress lead times?

Have regular and stable orders and want to compress lead time, talk to our sales engineer to find the best solution

WHY CHOOSE UNICORN

China Top 5 Trusted Staples & Nails Manufacturer

Moderate Price

Competitive prices combined with unparalleled quality ensure that every penny you spend is worthwhile.

Expert Sales Engineer

Our sales engineers combine deep industry knowledge, extensive experience, and fluency in English to facilitate effective communication.

Fast Delivery

Equipped with numerous advanced machines and more than 250 skilled workers, Unicorn ensures rapid and efficient manufacturing.

Quality Assurance

We guarantee reliability through stringent testing, ensuring our products consistently meet high standards of performance and durability.

Feel free to contact Our Sale Engineer

Whether you have product questions, need a customized quote, or want to explore business solutions, our sales engineers are just a message away. Contact us today for a prompt response and expert guidance – we look forward to supporting your success.

+86-15620082770

vincent@unicon-fasteners.com